Just how efficient is your shop? Do you have a true process that isn’t dependent on one person?

For many shops, if Billy doesn’t come in then nobody can mix ink or even ship. The “process” is locked in his brain.

If he isn’t available, then everything comes to a screeching halt.

It Doesn’t Have to Be That Way

Building processes can seem a little weird at first, but what you want to establish is your “shop way” of doing something.

What information you are collecting and how it is used?

How do you designate when the order has to ship?

The method of how you use the software?

Even what you call something!

It becomes less about how an employee like Billy handles things, and more about how anyone in your shop can complete the same task.

Sure, Billy is a rockstar employee…but there can be some challenges if he isn’t around or you are trying to scale your business.

Start Mapping Out Your Process

Before you can improve anything, you need to think about and measure how you do things now.

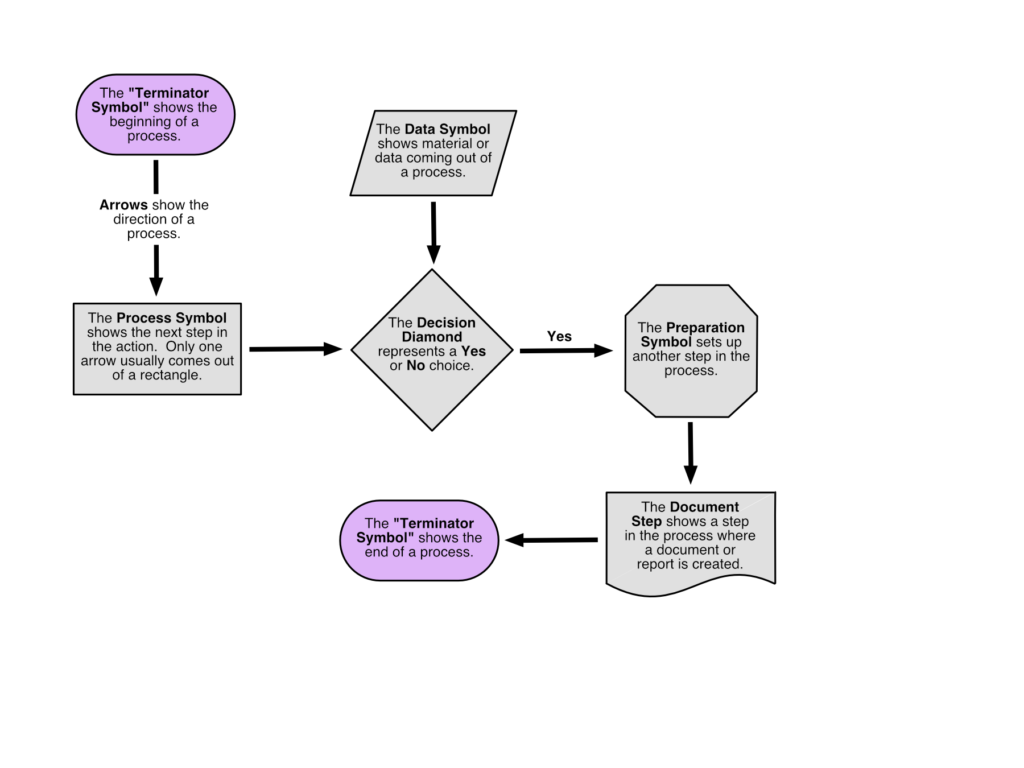

Process Mapping is the work that is used to visually define all of the steps and decisions in a specific process. A process map, (sometimes called a flow chart), is used to describe the flow of information, decisions, and tasks that are associated with the chain of relationships between the process steps.

The act of sketching out the flow chart to improve a process begin in 1921 with Frank Gilbreth to the American Society of Mechanical Engineers.

A process map can help you visually understand the relationships and key factors in your shop.

Include Everyone

It is vital to get everyone to share their thoughts. What do they need? Is there a problem or challenge? Can you list the goals of the process?

It is important to describe what success looks like.

Key factors for the person ordering the goods aren’t as relevant as to the creative team that has to process the art. But both groups have to have their work completed on time so that the order can ship by a certain date.

Get good feedback from everyone.

Grab Some Paper and a Pen

You want to diagram the workflow. What are the key ideas?

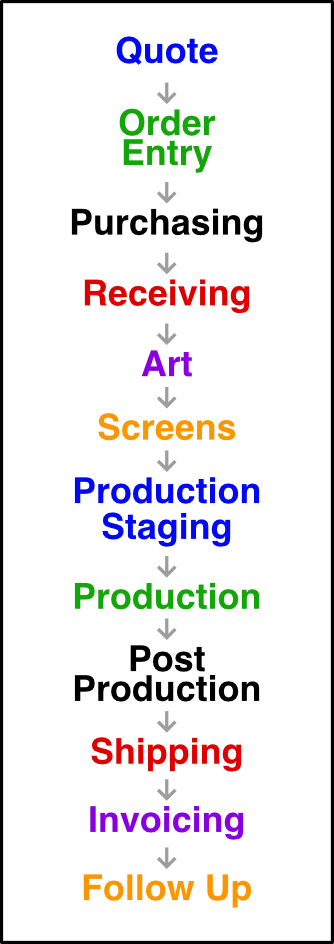

Here’s one for a screen-printing shop to get started.

What are the key steps for each? How is information used and carried over from one step to the next?

Think about the number one goal for your shop, which is that the order has to ship on the target date with quality and craftsmanship.

What challenges happen if one part of the process isn’t right? Maybe something gets delayed or entered wrong.

Process Mapping Steps

Here are some steps you could use to fix it by mapping out the situation:

Step 1: Identify the problem. Describe the situation.

Step 2: Get your team involved and brainstorm. Discuss all of the potential causes, solutions, and anything that can make a difference.

Step 3: Outline the limits of the situation. Where or when does the process start and stop?

Step 4: Determine sequence and steps. Here’s what needs to happen in priority order.

Step 5: Draw out your process map. If you want to chart with the correct visual language, follow these tips:

Using this mark up language you can chart your steps and map out what exactly needs to happen in your shop for each function.

This is how you build the “Shop Way” of doing every core task in your company.

Benefits of Process Mapping

It might seem a little daunting at first, but what you want to do is create the visual roadmap for success.

This will allow you to train your employees more effectively because it won’t be how “Billy” does things, but rather how the shop should do them.

Don’t forget that Billy can be instrumental in writing these steps.

Once you create your “Shop Way” of working, it is much easier to have a consistent, predictable, and repeatable future.

Good info. We are having growing pains. Time to establish a flow chart so we can be more efficient. Our problem is checking in all the products and pre press communications between sales and production. Never thought I would have to deal with this stuff and here it is.